concrete scanning

Advanced Ground Penetrating Radar Services

service overview

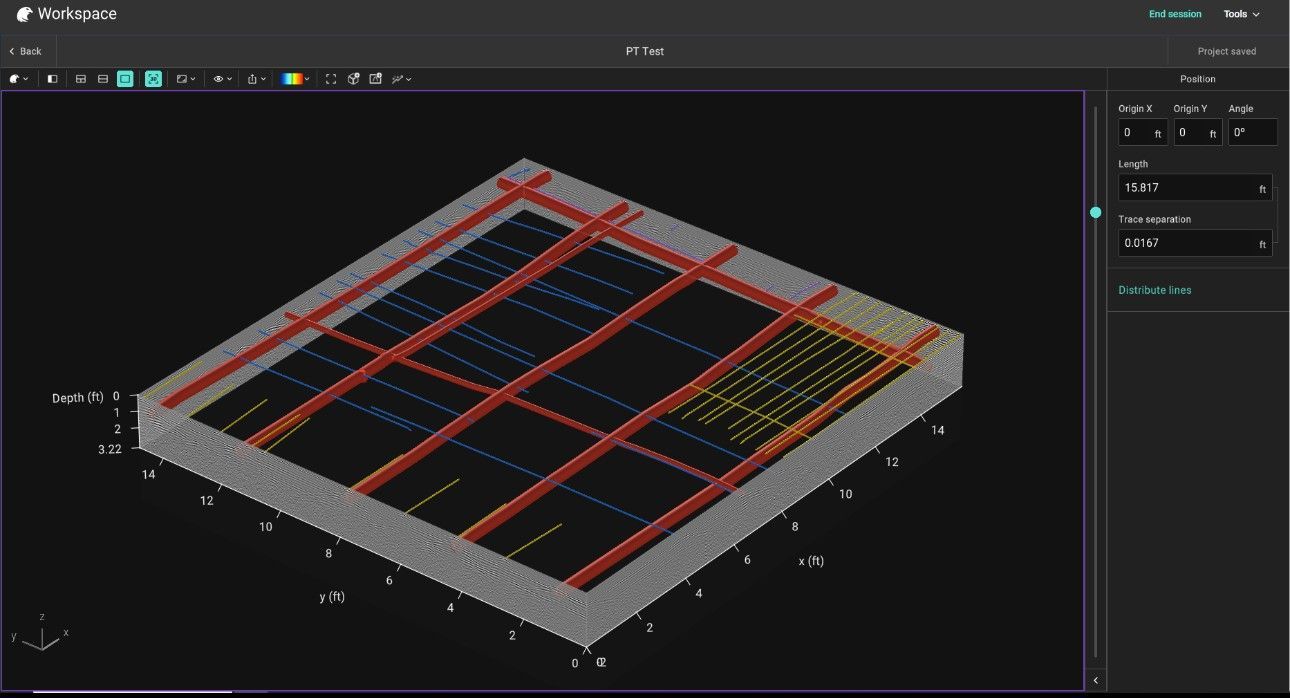

Multi-Channel Ground Penetrating Radar (GPR) is a variation of traditional GPR that uses multiple radar antennas simultaneously to collect data. In a multi-channel GPR system, several antennas are arranged in an array or a line and are connected to a control unit.

The main advantage of multi-channel GPR is the ability to collect data from multiple depths and angles simultaneously. This allows for faster data acquisition and improved imaging of the subsurface. By using multiple antennas, multi-channel GPR can provide a more detailed and comprehensive view of the subsurface compared to single-channel GPR.

Multi-channel GPR is commonly used in applications where high-resolution imaging and accurate subsurface characterization are required. It is often used for concrete condition analysis, structural analysis, geotechnical investigations, archaeological surveys, utility mapping, and environmental assessments.

The data collected by multi-channel GPR is processed and analyzed using specialized software to create detailed subsurface images and profiles. The interpretation of the data requires expertise in GPR data analysis and knowledge of the specific application.

Overall, multi-channel GPR offers enhanced capabilities for subsurface imaging and provides valuable information for various industries and research fields.

What are the Benefits of SFCW Multichannel GPR Data Collections?

Step Frequency Continuous Wave Multi-Channel GPR offers improved depth of penetration, high-resolution imaging, faster data acquisition, versatility, and non-destructive testing capabilities. These benefits make it a valuable tool for various applications that require subsurface imaging and analysis. Step Frequency Continuous wave multi-channel Ground Penetrating Radar (GPR) offers several benefits:

gpr Post processing

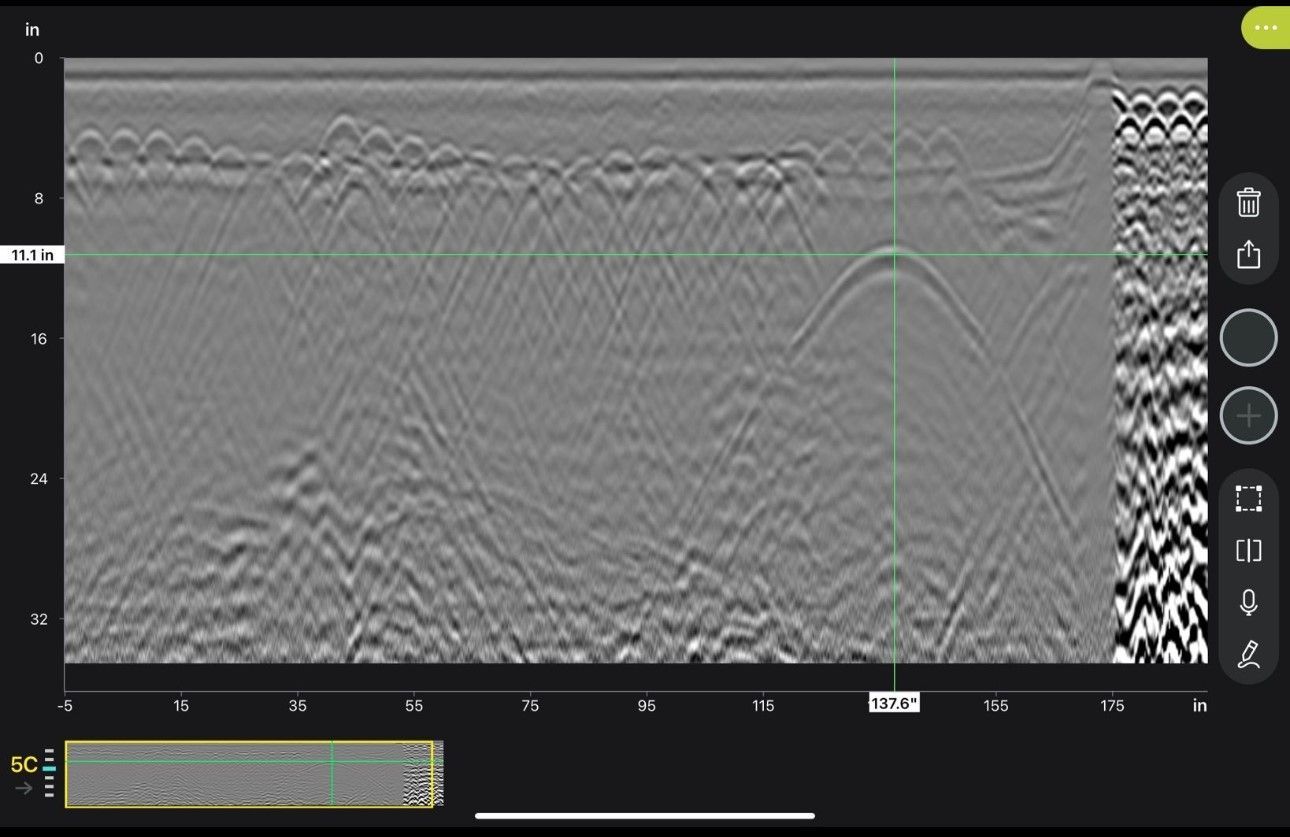

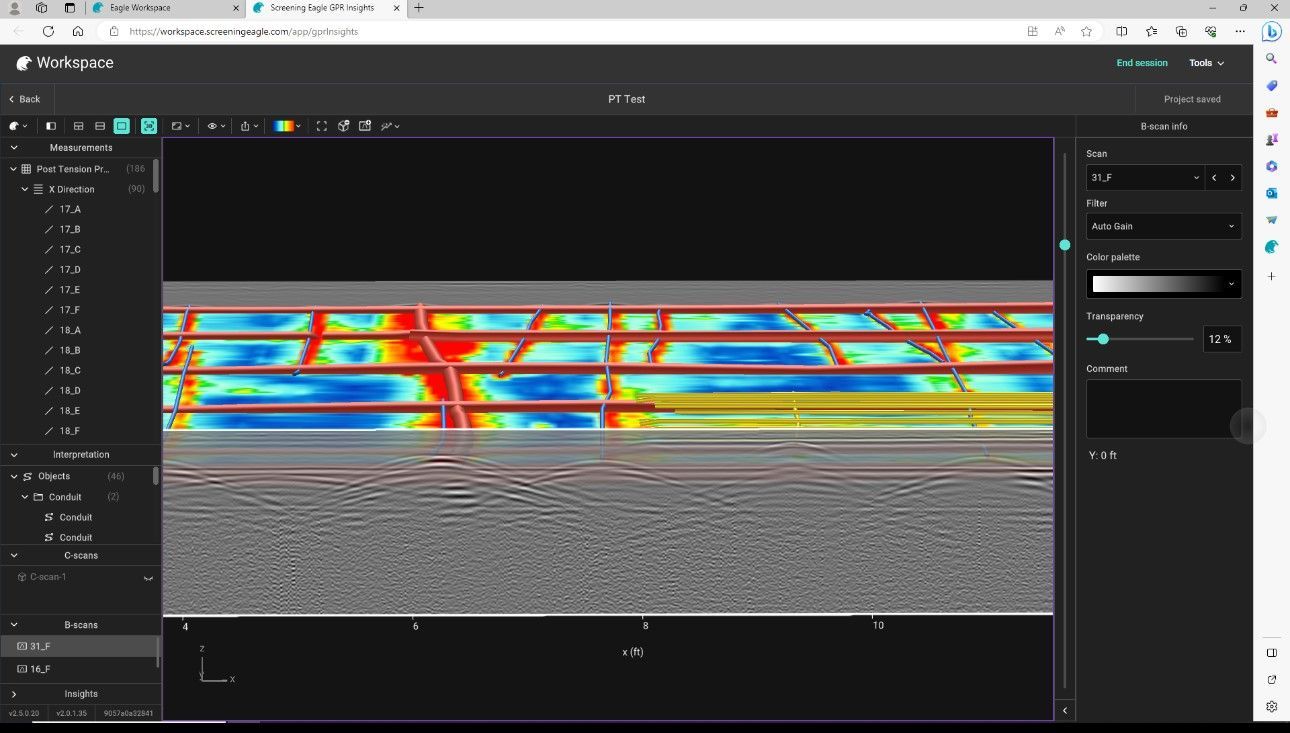

GPR (Ground Penetrating Radar) post-processing refers to the analysis and interpretation of data collected from GPR surveys. After collecting GPR data, it is necessary to process and analyze the data to extract meaningful information about subsurface structures and features.

Some common post-processing techniques used in GPR analysis include:

Post-processing software packages, such as GPR-Slice, IQ Maps and GPR Insights are commonly used for GPR data analysis and interpretation. These software tools provide a range of processing and visualization functions to help Cobra extract valuable information from GPR data.

subsurface features gpr can detect

Ground Penetrating Radar (GPR) concrete scanners can identify a range of items and features within concrete structures. Some of the most common items and features that GPR can detect include:

Receive a FREE Quote On Your Next Job

We pride ourselves on our commitment to complete client satisfaction and safety, and we have the reputation and track record to prove it.

Why Choose Us

We revolutionize the concrete sawing & drilling industry through our innovation & attitude, provide a level of service & passion that our customers, our employees & our community desire to experience.

Safety

Cobra emphasizes the importance of safety from start to finish of every project.

Relationships

Creating successful relationships while building trust during completion of all current projects and beyond.

Innovation

Better solutions and ideas to complete projects in a more timely and efficient manner.

gpr concrete scanning FAQs

We've compiled this comprehensive list of frequently asked questions to provide you with quick and informative answers. Whether you're a new customer seeking information about our offerings or a returning customer with inquiries about using our platform, you'll find valuable insights here.

Google Reviews

james hertz

I used to work with the owner's father for many years, trusting the company with my life. They are committed to fair pricing and completing the job on time, often ahead of schedule—more so than anything else.

Request a Quote

Thank you for your interest in our services! We pride ourselves on our commitment to complete client satisfaction and safety, and we have the reputation and track record to prove it.